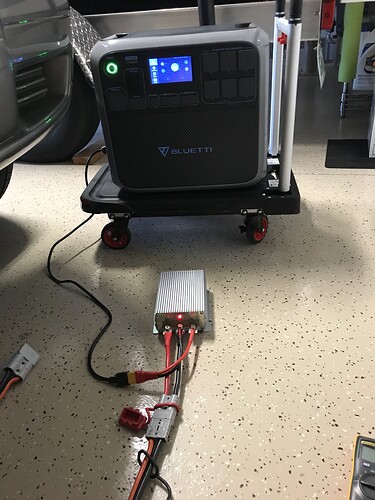

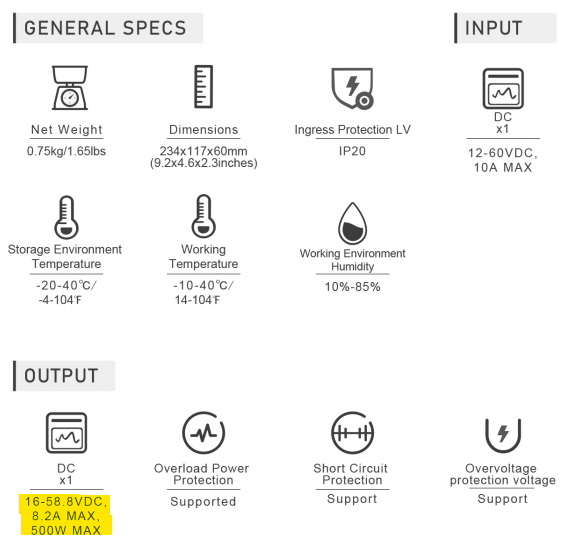

I recently purchased a 15 amp 12 volt to 48 volt DC converter with the intentions of seeing if faster charging my AC200 from a vehicle was feasible. Here is a link to the converter I chose:

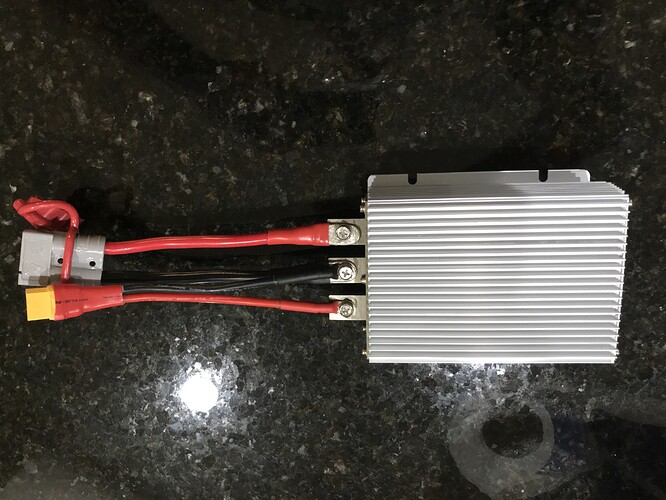

The description states 10 amp max but the item I was sent was clearly a 15 amp to 48 volt converter. I already had a 175 amp anderson connector installed directly to the battery of my Isuzu Trooper (80 amp alternator which is not much) and I wanted a portable quick disconnect system. I had a few extension cables already fitted with 50 amp anderson connectors so I made up a cable for the converter that would connect from a 50 amp anderson to the 175 amp anderson cable in the Trooper. Pic below:

IMG_6477|666x500 !

IMG_6478|666x500

Since My alternator was so small, I wanted to use heavy gauge cables and simply used battery cables for the input side and 10 ga. wire for the output 48 volt side to the XT90 connector.

RESULTS:

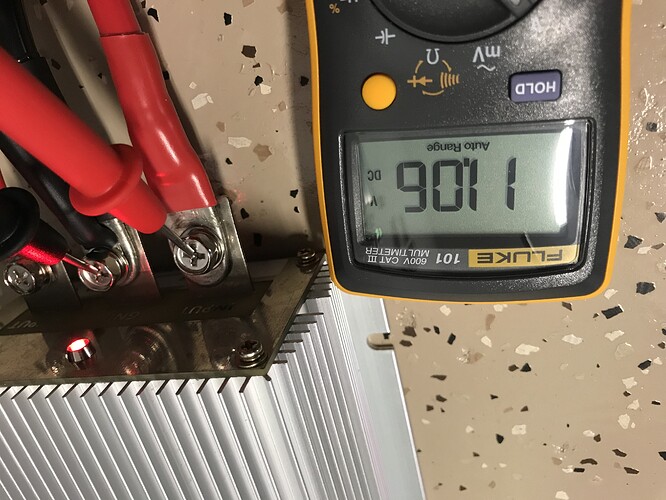

I was able to charge at a steady rate of 574 watts from 37% to full.

The alternator when idling was barely able to keep up with the approx. 55 amp demand and I was able to maintain 12.71 volts from vehicle battery. If I ran the engine at 2,000 RPM, I was able to maintain sufficient voltage unless I turned on both the headlights and AC so this was marginall at best. I connected a 30 amp AC charger to the vehicle (so I would not have to run the engine) to complete the full charge test.

The AC200 remained at 574 watts charging rate until full. The only issue is that the metal casing of the 12 volt to 48 volt *converter got hot enough that I could not touch the bottom for more than about 1 second. No problems were notice other than the hot running unit.

If I were to hard mount this unit in a vehicle that had sufficient alternator capacity, I would mount it with some stand off tubes so that the converter had at least 1/2" of clearance on the botom for air flow. I also think it would be a good idea to mount a small 12 volt PC fan that would constantly cool the converter. I previously tested a 24 volt to 48 volt converter and it did not run nearly as hot. I would also mount the converter absolutely as close to the vehicle batteries as practical with heavy ga. cable. This will maximize the voltage the converter receives which will lower the amp load and likewise will lower the heat output.

STAND ALONE (NO ENGINE RUNNING) 12 VOLT BATTERY TEST:

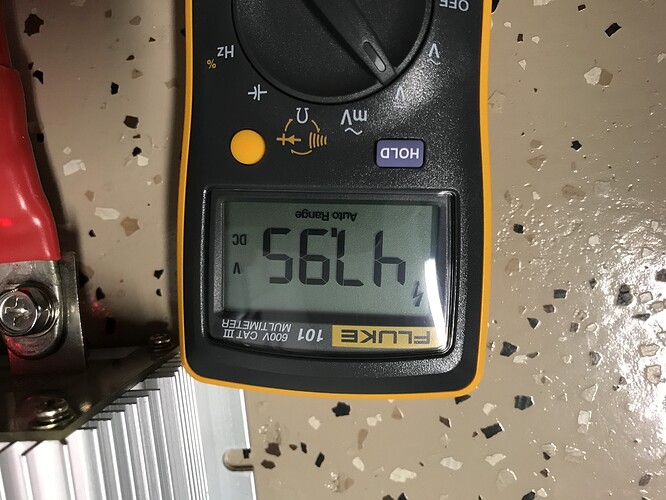

For the last test, I wanted to see how much charge I could put into the AC200 by connecting a 12 volt pair of group 24 AGM 2 year old batteries that each have a 78 amp hour capacity. They were connected in parallel and fully charged immediately before beginning the test. The beginning battery voltage was 12.99 under no load / 12.12 while under full charging load at beginning of test / 10.90 under load when test ended / 11.7 under no load at end of test.

RESULTS:

AC200 was charged from 0% to 54% in about 1 1/2 hours at which time the voltage converter no longer received sufficient input voltate and the charging rate began to fluctuate down to 174 watts. I discontinued the test as the under load voltage was less than 10.

The voltage converter was hot at the end of the test and the heating increased esp. at the end when the incoming voltage dropped causing a higher amp draw. The casing was uncomfortagle to grab, touch or handle and I would make sure whever it was mounted, that nothing could come into contact with the case that would be easily damaged by heat. The converter does say it has overtemp protection with auto restart, but it never did shut down so I assume the temps were within an acceptable range.

After performing this test, I think there may be a case where it would be advantageous to use a converter like this to use on board battery power alone to charge the AC200 quickly before operating or driving the vehicle. This should enable the vehicle batteries to charge at a much faster rate since full alternator power would then be transferred to charging the batteries via the existing heavy ga. battery cables.

All in all, If a 12 volt to 48 volt converter was available that could output only 10 amps even though it could be capable of 20 to 25 the case heating would be minimized. The challenge with this is that the AC200 wil be trying to pull the full 12 amp input load from whatever is connected and the converter will be overloaded.

Assuming you have a vehicle with a high capacity alternator, this set up while driving should give you the option of receiving a 574 watt incoming charge rate which would fully charge an empty AC200 in about 3 1/2 hours of driving or less if the AC200 was not fully depleted. The unit will draw from around 45 to 55 amps and you will need to plan for high amperage switch, 75 amp fuse or circuit breaker as well as heavy gauge cables on the input side. A 12 volt fan should not be too difficult to mount and could connect directly to the cable attachment points on the converter which would run the fan anytime the converter is running.