@CK0Co2 @ Scott-Benson

Thank you.

This is not a matter of liability, but of how to use the product safely without issues by knowing what the specs are. If you buy a picture hook in the store, it tells you not to exceed 5 pounds, or 10 pounds, or 50 pounds so you know which painting you can hang on which.

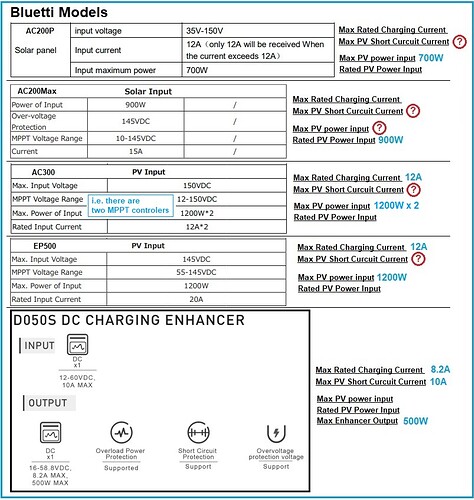

I have made a chart below of the specs and what is missing.

Yes, Voc is critical, but amps and panel wattage are important as well.

If you look up the specs on any MPPT controller, they always tell you the “ max rated charging ” output values and the “ max PV short circuit current” input values. Or they will tell you the “ rated PV power ” input and the “ maximum PV power ” input.

The difference between the two is the amount designed into the system to allow for safe over paneling. Above this amount excessive heat can be generated, or it can increase the open-circuit voltage of PV array. The designer intentionally determines the degree of over paneling by the specs of the components and the design of the container. Some MPPT controller designs allow no over paneling, others allow 8% or 20% or 50% or 100% or more. Generally, regardless of whether the controller allows it, going over 50% over paneling yields diminishing returns.

In any event you cannot guess at it. You need to know the design specs.

It should be obvious that if you over panel by 50% but the controller was designed for 8% you are going to get early failure of your equipment. On the other hand, if it allows 100% over paneling and you do none, you will get diminished charging in winter - extending charging time. Also, remember you rarely get the rated wattage out of a panel, except under ideal conditions. So, there is a balance.

Victron

https://www.victronenergy.com/upload/documents/Manual_SmartSolar_MPPT_100-30__100-50/MPPT_solar_charger_manual-en.pdf

For example, the Victron 100/30 MPPT controller documentation states “rated charge current” is 30A and the max “PV short circuit current” is 35A. This means it will charge at a max of 30a, but you can input 35a safely, meaning a 20% maximum over paneling is built into the design.

Epever

https://www.epever.com/wp-content/uploads/2021/04/XTRA-N-Manual-EN-V4.3ETL.pdf

Another example, the manual for the Epever Tracer XTRA3415N with a “rated charge current” of 30A says, “The maximum power of PV array shall be not greater than 1.5 x the rated charging power of controller.” And it gives the following 50% over paneling recommendations for this 30A charger:

Rated Charge Power Max PV Array Power

390w/12V 580w/12V

780/24v 1170w/24V

1170W/36v 1755W/36W

1560W/48v 2340W/48v

Bluetti

The specs for Bluetti, on the other hand, are confusing.

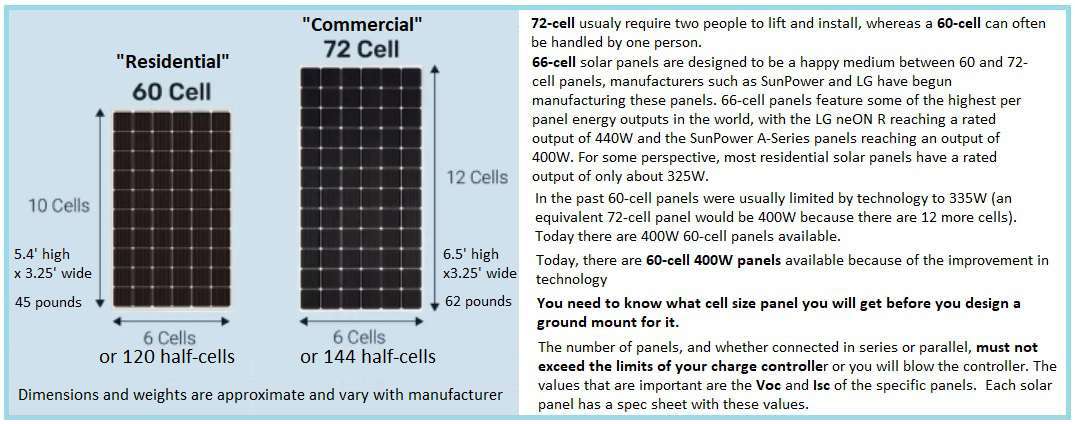

I made up a summary chart of the Bluetti specs to help my friend Paul decide which Bluetti he wants, if any. He is leaning towards the E300 but will not decide until we get a better handle on the missing specs to determine which panels to use, the important panel specs being Isc and Voc, and the missing Bluetti specs being the “max PV Isc.” Amps are stated in the Bluetti manuals, but it many instances it does not say if this is the “max rated charging current” or the “max PV Isc.” That is like saying the speed is 50 but not telling you if it is feet per second or mile per hour.

The only one with complete specs is the D050S Charging Enhancer. It clearly states the Isc is 10A.

I have put question marks where important data are missing.

From these specs, the only Bluetti panel that will work with the charging enhancer is the PV100 at 24.4Voc and 6.43A. The total Voc for 2 panels, plus an approximate 5% temperature correction factor, is 51.24v. For three panels it is 76.9Voc, so 3 panels will not work. Thus, with the Bluetti panels, the maximum that can be used are 2 each 100W panels on the “500W” charging enhancer.

The PV200 and PV350 will not work safely with this charging enhancer per the Bluetti specs of Isc 10.3A and 10.8A respectively.

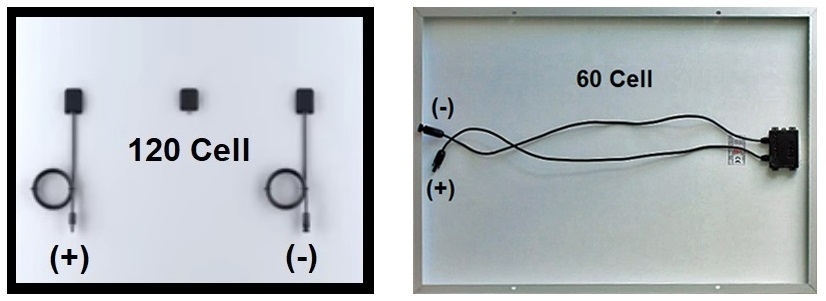

Furthermore, most of the standard 60-cell/120-cell, 72-cell/144-cell rigid panels will not work with it either. Most exceed 10A – and the others are right on the edge at 9.82A. I do not want to mix panel sizes on my array, so this enhancer is kind of useless to me and I will return it. It is under powered and not worth the expense and trouble for just 200 watts.

Yes, some people are saying they are using more watts and more amps and they are okay. I say, yes, okay for now. But you are voiding your warranty and stressing your equipment beyond the specs so your equipment will die an early death.

These specs also say the AC200P “input max power” is 700W. Provided the person that wrote the specs was an engineer and knew what they were doing, means it cannot be over paneled beyond 700W safely without voiding the warranty and stressing the equipment.

BottomLine

- Need clarity on the Bluetti specs, especially max Isc panel input and max panel wattage input to the Bluetti. In many cases it just says watts or amps not saying if this is max charging or max input.

- The charge enhancer is too under powered, and I canceled my order.

- I like my AC200P it is running well. It is a bit underpowered for handling panels but at the price, it is a good unit. I have found a couple of 350W rigid panels that are compatible with the AC200P specs but the shipping cost is outrageous, or in some cases, they will only ship you a bundle of 10 panels. No one locally sells panels. Only the installers have panels and they do not sell them.

- I realize Bluetti is a young company and glitches, like the lack of clarity in the specs, are to be expected now and then. Hopefully, these will clear up as time goes on.

- Overall I researched 16 manufacturers and like Bluetti the best.

Is there any way we can get the missing data from the spec sheets? As a first approximation, I can posit that the currents shown are the “max PV Isc” and not the “max rated charging current,” but that will cut down the choices of panels available because many will exceed 12A. Half the panels in this size are 14A.