Final Update: So Far Jan 31 / 2022

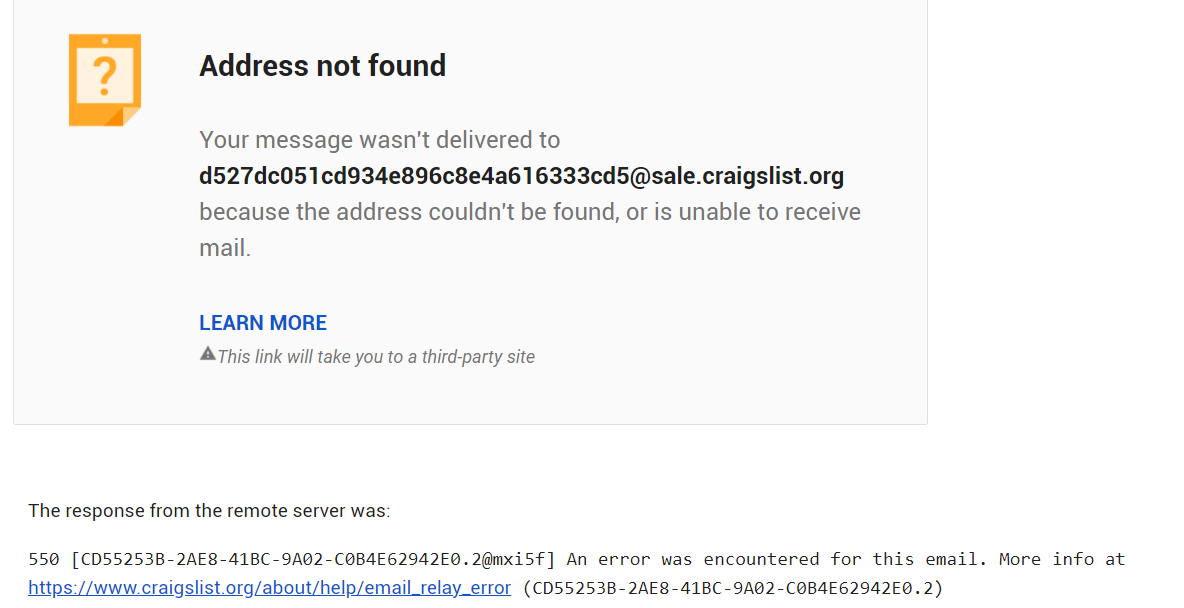

Bluetti diagnosed the problem via a video and sent me a new BMS as replacement (One of the mofsets came bent as if it was dropped, but i don’t think it will affect too much I hope.

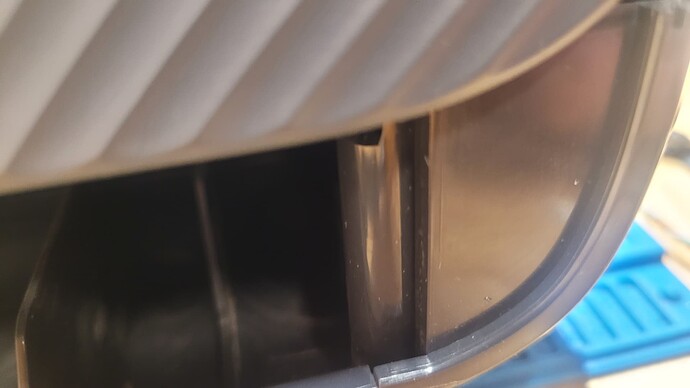

One other big issue i foresee for reparability is the handle mounting points. The 4 mounts for the handle are simple brass inserts into a weak injection molded column (pictures). The outer skin (grey corner borders) is likely strong enough to help support this but the handle nuts simply cracked off when tightening the handle nuts.

Any AC200p owners out there, i would advise to be extra careful when picking up and putting down the unit. i don’t think it would take much force to dislodge those brass inserts and render your handles useless. Also i would be cautious when carrying the unit as it may already be broken and just held on by the plastic skin. If your handle is loose, this is likely the case and unrepairable without a brand new case

I am going to install some small nylon strap to distribute the load over the entire bottom to the handles.

@BLUETTI I would love to see this supported with an aluminum brace mounted outside of the bottom of the AC200 (Or any heavy case from now on) Spread the force over the entire plastic shell rather than small failure points.

Overall:

Functional components, modularity of parts, good labels, forethought, makes fixability a 9\10 for a skilled technician.

Physical components (Case, plastic, handle mounting) i would rate this at a 2 / 10 for fixability. The corner bracket skin is a disposable part. All the mounting barbs on it are one way. Meaning it’s physically impossible to remove without snapping them off. So be warned if you are fixing the device you will likely suffer damage to the outside skin (removing it breaks mounting points off as well as there is super adhesive double sided tape). And may suffer weak mounting points for the handles (2 snapped off on mine at a very low torque, on the power inlet side).

I’m happy with the support @BLUETTI provided. They went above and beyond. it did take a long time, but I understand it’s not part of their process… yet. I would love it if they take the time to release a service manual with proper procedures AND maybe sacrifice some cosmetic aesthetics for functionality in the future.

-

Add screw hole mounting for the skin instead of snap off barbs. Allowing for the repair to be done locally without the costly need to send units back and forth to repair centers.

-

Add an aluminum bar on the underside for securing the handles to, distribute the weight more evenly and not rely on 4grams of brass to support 60 pounds. I feel like this is a huge liability. If an owner roughly sets the device up high (back of a truck) and breaks the mounts. The next time they pick up the unit, 1 or both handles have the ability to come loose and drop 60 pounds directly on a foot, or child standing close or pet.

If anyone is interested, i privately uploaded the videos to youtube and can share those.